Highlights

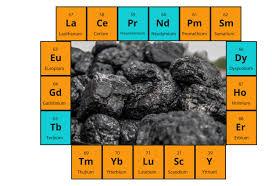

- Northeastern University researchers developed a method combining sodium hydroxide pretreatment, nitric-acid digestion, and microwave heating to extract REEs from coal tailings 2-3 times more efficiently than standard approaches, with up to 23× improvement for light REEs.

- While the chemistry is sound and targets critical neodymium for EV motors and wind turbines, industrial scalability faces hurdles including variable coal tailings composition, unproven continuous microwave processing, and costly waste management of radioactive co-constituents.

- Coal tailings may serve as supplemental feedstock but won't bypass China's downstream dominance in separation, processing, and magnet manufacturing—the true strategic bottleneck in the rare earth supply chain.

A January 8, 2026, Northeastern Global News feature (opens in a new tab) says Northeastern University researchers can extract rare earth elements (REEs) from coal tailings two to three times more efficiently than “standard” coal-byproduct approaches by combining sodium hydroxide (lye) pretreatment, nitric-acid digestion, and microwave-controlled heating.

Table of Contents

What’s Real: The Chemistry Has Teeth

At the bench level, the mechanism is plausible and well-described: alkali treatment can restructure aluminosilicates (e.g., kaolinite transforming or dissolving), which improves REE liberation during subsequent acid digestion. In the underlying study, the authors report ~2–3× improvement for light REEs depending on the structural pathway achieved under microwave conditions, with more modest gains for heavy REEs.

The news story’s emphasis on neodymium also tracks the supply-chain “why”: Nd (with Pr) feeds NdFeB permanent magnets, the torque behind EV traction motors and wind turbines.

The study (opens in a new tab) was published in Environmental Science & Technology, led by Lawrence O. Ajayi, (opens in a new tab) as well as corresponding author Damilola A. Daramola (opens in a new tab) and colleagues at Northeastern University Department of Chemical Engineering.

What’s Missing: Scale Eats Headlines for Breakfast

This is where investor-grade skepticism belongs. Coal tailings vary sharply by basin, seam, and processing history, so “works in Pennsylvania” does not equal “works nationally.” Microwave reactors can accelerate heating and kinetics, but continuous, high-throughput microwave leaching with aggressive reagents is not yet a widely proven industrial template for REEs—especially once you price in reagent recovery, materials handling, and permitting.

And the inconvenient footnote: tailings can carry radioactive and nuisance co-constituents. An industrial flowsheet must manage waste liquids, residual solids, and multi-element separation—the real cost center.

The China Frame: Not Wrong—Just Over-Simple

Yes, China dominates the bottlenecks—especially separation/processing and magnet manufacturing. But as we try to convey frequently at Rare Earth Exchanges™, the strategic moat is downstream capability, not merely alternative feedstock. Claims of ~90% processing/separation dominance are common in policy analysis.

Coal tailings may become a supplemental feed, not a shortcut around solvent extraction, product specs, and qualified supply.

Citation

Northeastern Global News, Jan. 8, 2026.

©!-- /wp:paragraph -->

0 Comments