Highlights

- Permanent magnets are a major focus in rare earth discussions, but trace rare earth element (REE) dopants like Nd, Y, and Ho play a critical role in multilayer ceramic capacitors (MLCCs).

- MLCCs are vital across various sectors such as defense, automotive, and aerospace due to their critical electronic functions.

- These capacitors use only micrograms of rare earths per unit; however, there are no practical substitutes that can offer the same level of electrical stability and reliability at the atomic level in barium titanate ceramics.

- To break China's dominance in the rare earth sector, rebuilding processing intelligence is crucial, rather than merely enhancing mining capacity.

- Institutions like KU Leuven's SOLVOMET Group are crucial for training the next generation in separation chemistry and materials science for functional rare earth applications.

When rare earth elements (REEs) enter public debate, the spotlight almost always lands on permanent magnets—the heavy hitters inside EV motors, wind turbines, drones, and missile actuators. But as Professor Koen Binnemans, one of the world’s leading rare earth scientists, reminds us, this focus misses a quieter, equally strategic truth.

Rare earths are not only the muscle of modern technology.

They are also core to its nervous system.

Table of Contents

The Invisible Role of Rare Earths in MLCCs

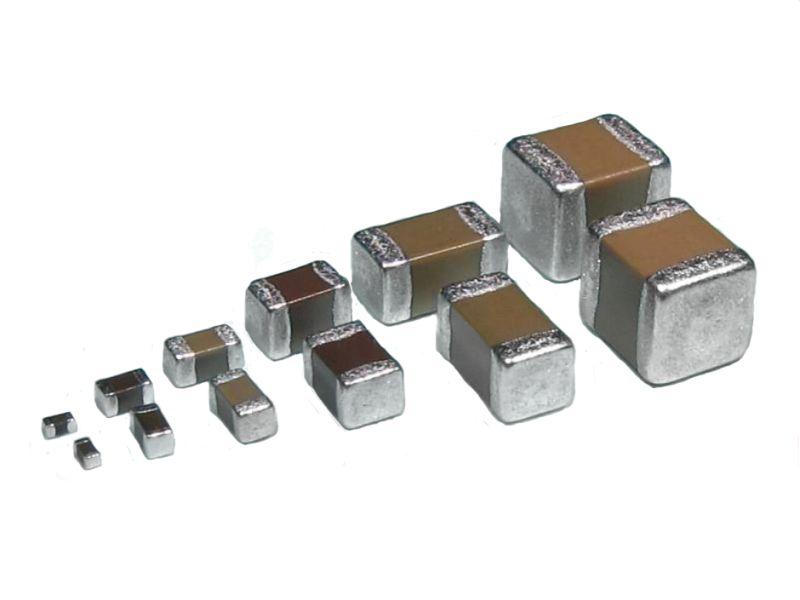

Multilayer ceramic capacitors (MLCCs) are among the most ubiquitous components in modern electronics. A single smartphone may contain more than a thousand; advanced vehicles, industrial machinery, and defense platforms can contain tens of thousands.

MLCCs regulate voltage, smooth signals, suppress noise, and ensure reliability under extreme electrical stress. Without them, electronics simply do not function.

What is far less understood—outside specialist circles—is that rare earth elements are essential to making MLCCs work at all.

As Binnemans explains recently online, REEs such as neodymium (Nd), yttrium (Y), and holmium (Ho) are used as dopants in barium titanate (BaTiO₃), the ceramic heart of MLCCs. These dopants operate at microscopic levels, yet their impact is profound.

Neodymium, in particular, is widely used because its ionic radius sits almost exactly between those of barium and titanium, allowing it to substitute at both lattice sites. This positioning enables Nd³⁺ to act as a powerful regulator of material behavior.

The results include:

- Controlled grain growth during sintering

- Reduced oxygen-vacancy defects

- Longer lifetime under high electric stress

- Precisely tuned Curie temperatures

- Stable capacitance across wide temperature ranges

These are not marginal gains. They are non-negotiable requirements for electronics used in aerospace, automotive control systems, radar, communications, guidance, and electronic warfare.

According to Professor Binnemans via LinkedIn:

“MLCCs are compact, high‑reliability capacitors made by stacking alternating layers of ceramic materials (such as barium titanate, BaTiO3) and metal electrodes, then sintering them into a monolithic block. They are the most widely used capacitor type in modern electronics because they offer high capacitance‑per‑volume, excellent frequency characteristics, and long-term stability.”

Small Quantities, Outsized Strategic Importance

Here is the paradox policymakers often miss.

Permanent magnets consume rare earths in bulk—typically 25–35% by weight in Nd-Fe-B magnets. MLCCs, by contrast, use REEs only as trace dopants—often ~0.1–2 mol% of the ceramic dielectric. Each capacitor contains only micrograms of rare earths.

And yet, the strategic importance of REEs in MLCCs may rival that of magnets.

Why?

Because there are no practical substitutes that deliver the same electrical stability, lifetime, and reliability at scale—and because MLCCs sit upstream of virtually every advanced electronic system. If MLCC supply chains fail, entire defense and industrial platforms fail with them—quietly, instantly, and completely.

This is why Professor Binnemans’ point matters: rare earth dependency is not just about tonnage; it is about function.

Why This Matters for Ex-China Supply Chains

China’s dominance is not limited to magnets or mining. It extends deep into materials science know-how, dopant chemistry, and processing expertise—the capabilities required to produce MLCC-grade materials with atomic-level precision.

Breaking that dependency requires more than opening mines. It requires rebuilding chemical intelligence, not just capacity.

That is where institutions like SOLVOMET come in.

Profile: SOLVOMET Group — Quietly Rebuilding Rare Earth Know-How

SOLVOMET Group (opens in a new tab) is one of the most important—and least publicly understood—actors in the ex-China rare earth ecosystem. SOLVOMET is a research and innovation center at KU Leuven, Belgium (opens in a new tab), focused on developing sustainable, low-energy, circular hydrometallurgical processes for mining, recycling, and chemical industries, helping companies recover critical metals from ores, waste, and residues using advanced lab-scale and pilot-scale facilities, with a vision for eco-friendly metal production for a climate-neutral society.

Led by Professor Koen Binnemans, SOLVOMET focuses on:

- Advanced solvent extraction and separation chemistry

- High-purity rare earth metals and compounds

- Circular-economy approaches, including recycling and urban mining

- Tailored rare earth materials for functional applications, not just bulk commodities

What makes SOLVOMET strategically important is its emphasis on processing intelligence—the very layer where Western supply chains are weakest and where China’s advantage is most entrenched.

SOLVOMET trains the next generation of metallurgists and chemists who understand rare earths at the ionic, lattice, and defect-chemistry level—the knowledge required for MLCC dopants, high-performance alloys, and advanced electronic materials.

In an era when rare earth discussions are dominated by megadeals, price floors, and mine permits, SOLVOMET represents something more fundamental: the rebuilding of scientific sovereignty.

Without groups like SOLVOMET, ex-China supply chains risk becoming hollow—able to mine materials, but unable to turn them into the precise functional inputs modern technology demands.

Final Thought

Rare earth strategy is not just about mines or magnets.

It is about materials mastery.

And as Professor Koen Bingeman makes clear frequently online on LinkedIn, the smallest applications—measured in micrograms—may ultimately carry the greatest strategic weight.

0 Comments